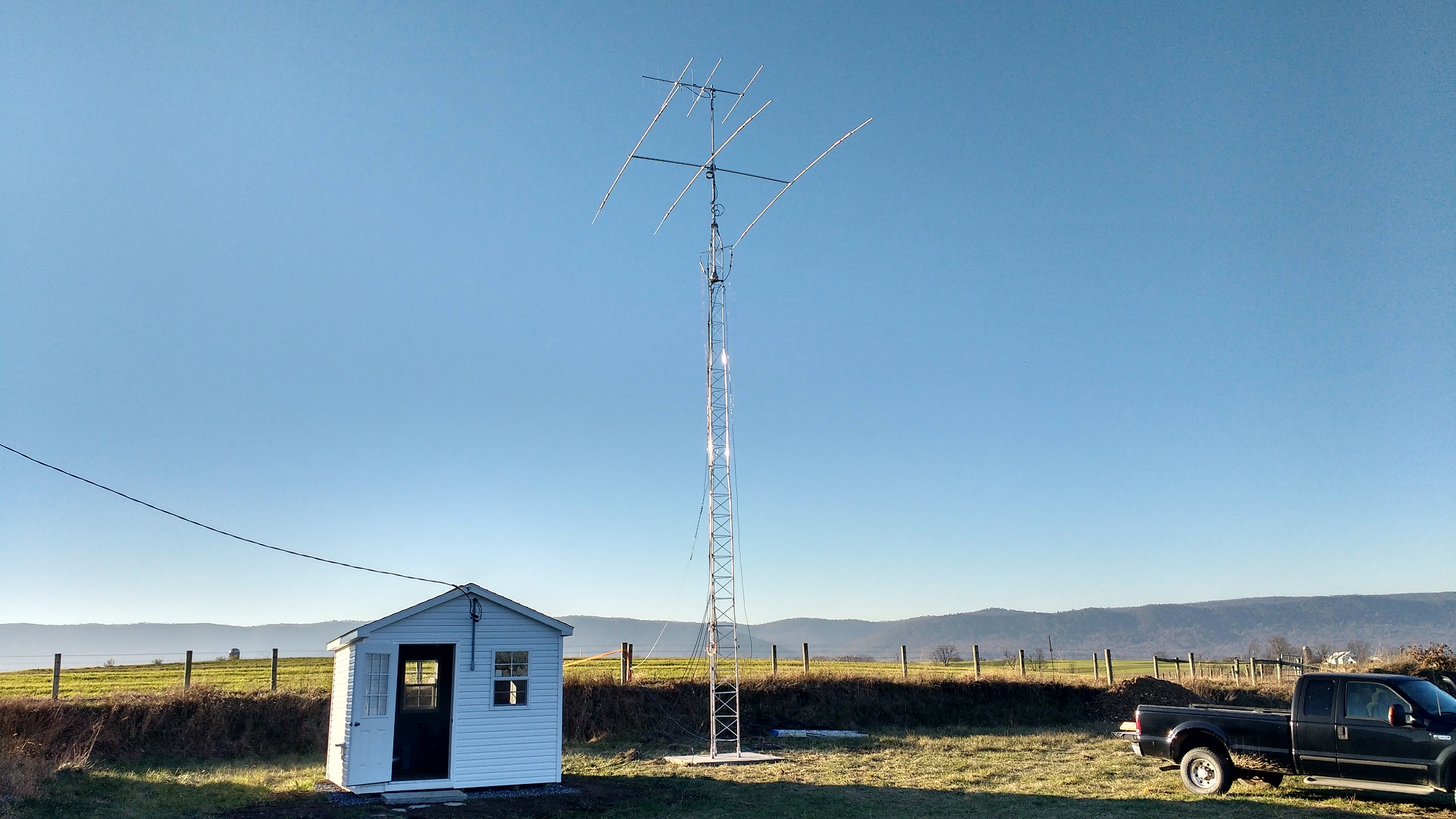

The shack and tower soon after construction

The antennas on the tower after adding the KA2C 160/80 meters inverted vee and tower-top band segment switch box – a 40 meters inverted vee is attached to the tower a few feet higher than the 160/80 antenna

Operating position with Yaesu FTDX101d and Heathkit SB-220 linear with 160 meters added

Backup operating position with Heathkit SB-101 and SB-220 linear and HD-1410 keyer – the remote VFO, TX scope and station console are for future renovation

Operating position with Heathkit HW-101, SB200 and SA-5010 memory keyer

Operating position with Heathkit TX1 and RX1

WRL Globe King 500B wtih external VFO and Collins R-388 – The R-388 is in good operating order and the Globe King 500B is for future renovation

Cows in the sky – 40 foot tower with Ham IV rotator, Cushcraft 3 element A3S for 20/15/10 at 45 feet and Cushcraft A627013S for 6/2/70cm at 50 feet

The ground system is a critical part of the radio shack for protection against electrical shocks, protection against lightning and control of RFI. On the wall behind the benches runs a 10 foot 3/4″ copper pipe for ground connections. It is connected with #4 copper wire to the external ground system just through the wall behind the benches where it is bonded to: 1) the tower ground system; 2) the electrical ground system; and 3) the shack external ground system composed of 6 ground rods spaced on 3 sides of the shack. Radio equipment, auxiliary equipment, computer and audio equipment are connected with short heavy copper wires to the copper pipe using standard copper pipe ground clamps. MFJ cable feedthrough panels mounted in the wall are connected directly to the ground system and are equipped with lightning arresters for the antenna coaxes and the rotor control cable.

HVAC

A comfortable radio shack is a must. A Mr Cool Do-It-Yourself mini-split HVAC unit was installed in 2020. This is an 18,000 BTU unit and provides plenty of cooling power for hot summer days as well as heating in mild to moderate cold. The space high on the end wall was convenient to avoid using equipment and operating space. It can be controlled and monitored over the Internet. Installation of this unit can be done without any specialized equipment such as vacuum pumps, gas pressure gauges,…. It comes charged with refrigerant and with fairly simple instructions. It came up with no problem after carefully following the instructions, but it take a number of steps to install. With the fan set to low and the louvers directed upwards, the unit is very quiet with only a very gentle breeze, but easily keeps the shack comfortable.

A 4 inch conduit covers the line-set from the indoor unit to the outdoor unit.

The outdoor unit connects to the 220V power and to the line-set.

This RF choke on the power/signal line connecting the outdoor and indoor units suppresses spurs in the HF ham bands with 35 KHz spacing which appear to be harmonics of a switching supply. After this was installed the spurs were into the noise and barely noticeable but they could be found with careful listening on most HF bands. On 20 meters they were a bit louder but still quite weak just above the noise. Overall, the spurs are expected to very rarely be an issue with this fix. The core is 2.4 inches using toroid core mix 43.

A smart WiFi Honeywell thermostat for the radio shack can be controlled from anywhere with web access on a smartphone. It is connected with a 24 VAC transformer for power and a contactor (relay) which sends 110 VAC power to a 1500 watt baseboard heater when needed. This allows me to heat the shack without using the Mr Cool mini-split unit and avoids any RFI issues since it is a simple passive baseboard heater. The Intermatic device is a surge protector connected to the electrical distribution box to protect against lightning surges on the power lines. In addition, I have a WiFi controlled outlet for a secondary milkhouse 1500 watt heater to help warm up the shack in very cold weather (it also can be controlled remotely).