Placing the rebar cage into the 5′ x 5′ x 5′ base hole using a boom on the front-end loader

KA2C (Nelson Sollenberger) wiring the rebar to the tower base and adding stabilization wires

Pouring about 7 yards of concrete with the tower base and first 10 foot tower section in place

A tower MUST be adjusted for perfect level before and during the concrete pour – Two large carpenter levels placed at 90 degrees were used for precise leveling for this tower

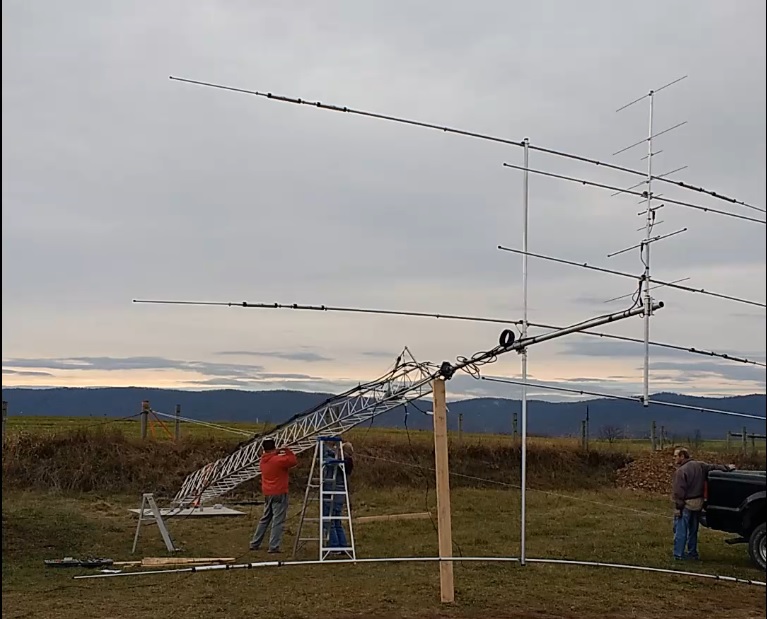

The Universal 40 foot fold-over tower with Ham IV rotator and 16 foot mast, antennas and coax feed lines ready for raising

Raising the tower with friends lifting on each of 2 attached legs and a winch from the truck connected via a pulley on a fence post to a point on the 3rd leg at about the 25 foot point on that leg – The fence post is braced to 2 other fence posts

Each tower leg is connected to a dedicated ground rod and a dedicated buried #6 solid copper ground wire – An aluminum clamp connects to each tower leg which is also aluminum and stainless steel sheeting isolates the aluminum clamps from the copper ground wires – All tower leg ground rods are bonded together with ground wire circling the tower base – The tower leg closest to the shack bonds to a similar ground system for the shack.

Plowing in ditches for ground wires for each tower leg

Using the Ford and 3-point hitch blade to fill in the ground wire ditches